The products of the food and beverage industry are of vital importance for people, as eating and drinking are one of the basic needs that every human being has. This applies regardless of the age of the entire world’s population in any place on earth.

The production and processing of food and beverages often require state-of-the-art machinery and systems. In addition, logistical conveyor routes within these production facilities have to be managed in both a linear direction as well as along curved sections.

Conveyor technology in the food industry

The beverage industry requires machinery and systems for the production of its products, which fill and move bottles or even casks, for example, at very high speed. The manufacturers or these machines and systems are often established mid-sized companies. These machines are almost always equipped to feed and discharge, connected upstream or downstream, which are equipped with rollers among other equipment.

With feed and discharge devices for the beverage industry, it is important that the rollers secure the beverage containers, which are often casks or barrels, laterally in the conveyed direction. As the weight of these casks when filled increases considerably, the rollers must also be very stable. In addition, it is important that the rollers are low-wear and will thus operate flawlessly over longer periods. With heavy conveyor items such as filled barrels, it is important to position and move them safely, in the right position and direction. Some of these conveyor movements may also involve curved sections. In such cases, the use of tapered rollers is required. This also means different sized curve radii can be managed. The challenge is also that the shapes and sizes of casks often vary, so that even greatly fluctuating weights have to be handled safely. The filled items must be conveyed safely and precisely and must not tip over under any circumstances.

Conveyor technology and food

In breweries, part of the everyday routine is that all kinds of beer barrels in various sizes both empty as well as full have to be moved and transported over long distances. For this it is sometimes necessary for the rollers to be replaced on an existing conveyor system, in order to ensure day-to-day operations run safely and reliably.

For heavy goods, such as empty or even filled beer barrels, rollers with recessed roller bottoms are suitable. To secure them laterally, which is necessary for safe linear movement, the rollers are fitted with guide disks, so the beer barrels with pallets cannot slide sideways. We do not regard these replacement rollers as a purpose-built design. We can meet these challenges with products in our extensive standard range.

Food industry conveyor belts

Whenever rollers on feed and discharge devices for the beverage industry have to be replaced, such as in breweries, this can be done very promptly without any major production downtime. Only the basic specifications and requested details have to be clarified with the technical department. After this, the order can be carried out immediately.

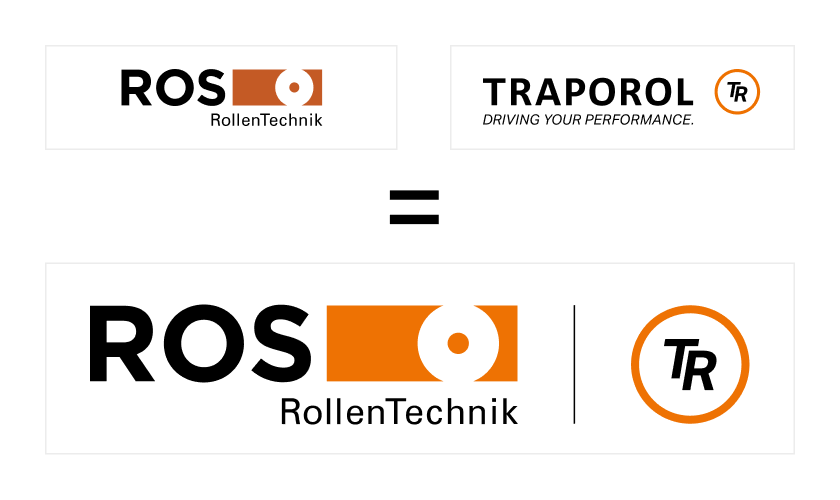

ROS RollenTechnik does not conclude any service contracts with its customers for the maintenance of rollers, as we regard these products as subject to wear and tear. In return, we offer contracts that ensure deliveries at short notice of any requested replacement of rollers in any quantity.

Conclusion

The main benefit for our customers is that if disruptions occur in operations of feed and discharge devices, they do not have to be completely dismantled or replaced but the problem can be solved by replacing individual parts. It is often enough to replace defective rollers with a new one, which reduces downtimes and the associated production losses to an acceptable minimum. In addition, it is particularly advantageous for our customers that we have a wide and extensive range of standard rollers. It means we can also respond properly and at short notice to unusual customer requests, associated with various size differences for goods to be conveyed. This particular flexibility of adapting to various products of our customers is becoming increasingly important.

We provide our customers with ROS RollenTechnik performance to the fullest extent. Starting with quotations, project management, procurement, contract drafting with scheduled quantities and delivery dates, the concerns and requests of our customers are the focus of our attention. This also includes delivery schedules, forwarding agents, and special packaging to avoid transport damage. Our full commitment in all these areas enables and ensures an orderly and regular production process for our customers.

Our customers are happy to choose ROS RollenTechnik as a supplier, as we normally provide a suitable carrier roller for testing, especially if it involves a potential new customer. As soon as this new customer is aware of the increase in efficiency and performance due to our product, which is normally the case, nothing stands in the way of a successful business relationship based on mutual trust.